Thin Section Bearings

We can provide you with the leading ball bearing information

Thin Section Bearings are a family of very low profile cross section bearings (thickness and width) that start at 1” ID and are available up to 35” ID. This family of product is suitable in applications that require low weight, increased space, reduced friction, increased design flexibility, and require excellent running accuracy. These products are used in Medical Equipment, Semiconductor Manufacturing Equipment, Robotics, and other industries. Thin Section Bearings are available in three physical configurations: Radial Contact, Angular Contact, and 4-Point Contact.

Thin Section Ball Bearing Products

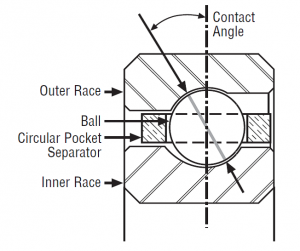

Radial Contact – C Type This bearing is designed with and inner and outer race that both contain two shoulders with a race depth to accommodate radial and axial loading. The bearing is assembled using the Conrad type assembly method. |

|

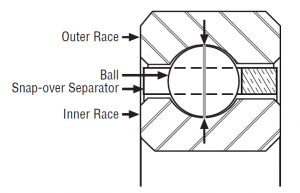

This bearing is designed with a relieved outer race. Angular Contact bearings can accommodate high axial loads in one direction only. If two Angular Contact bearings are used in the proper arrangement, a combined axial, radial, and reversing load. The bearing is assembled using the Angular Contact type assembly method.

|

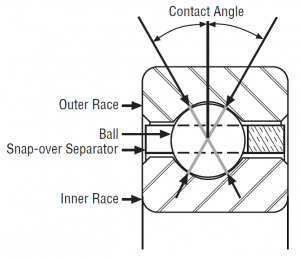

4-Point Contact – X Type This bearing is designed with Gothic Arch raceways in both inner and outer race so that the ball makes contact at 4 points (versus 2 in a standard bearing.) This bearing can accommodate a moment and reverse axial load. It is not recommended for a pure radial or combined radial and axial load. |