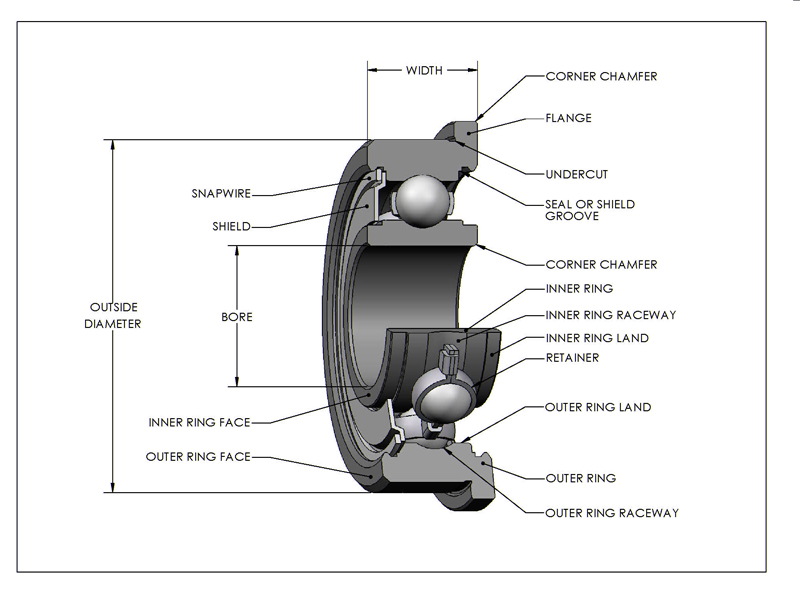

Bearing Overview

Ball bearings are used around the world in mechanical assemblies and applications – automotive, consumer products, appliances, medical equipment, and many more. There are various types of bearings but ball bearings are the most common. Ball bearings have balls as the rolling element which allows for very low rotating friction, but also allows for both radial & axial loading. Below is a cross section model describing the various components that make up a ball bearing.

Materials

The two most common types of materials used for ball bearings (the rings and balls) are chrome steel and corrosion resistant steel (corrosion resistant steel is commonly referred to in the industry as ‘stainless steel’.) These materials play a very important role in the life of the system and how the bearings will operate in the application, so understanding and selecting the proper material is vital in the performance of the bearing.

- Chrome Steel : SAE 52100; SUJ2; 100Cr6; GCr15 (low carbon steel with hardness Rc 60-66)

- Stainless Steel: AISI 440C; SUS440; X102CrMo17; X65Cr13; 9Cr18 (martensitic steels with hardness Rc 58-62)

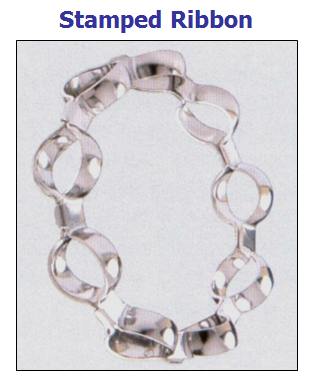

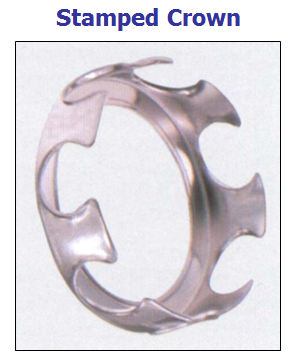

Cages and Retainers

Cages (also referred to as retainers and separators) serve the primary function of equally separating the balls in a ball bearing around the pitch diameter of the bearing. They are not normally designed to support loading other than frictional forces exerted by the rolling elements as the bearing is operating. The two most common types of cages are one piece stamped crown & two-piece stamped ribbon type.

- Other retainer options – in special applications you may need to have a non-standard retainer. The most common reason for needing a non-standard retainer is very high speed applications.

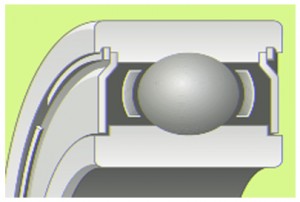

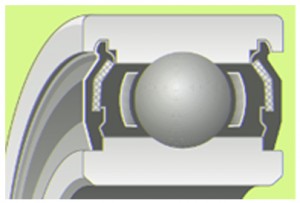

Shields and Seals

Most bearings have closures – shields & seals. When designed and manufactured properly, shields do not contact the inner ring while rotating so additional friction is not introduced into the bearing from the shield. Seals typically make a positive contact on the inner ring and are designed to seal against dust and other contaminants that can get into the bearing and wick out the grease.

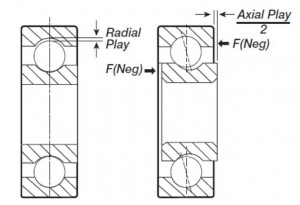

Radial Play & Axial Play

Bearings are designed with a certain amount of internal ‘looseness’ where the inner ring and the outer ring are able to move slightly with respect to one another. This movement is called Radial Play & Axial Play and they are interrelated – increase one and the other will increase as well (although at different rates.) Typically the radial play & Axial Play are removed in the final application when the bearings are mounted and pre-loaded using a spring or another preload method.

.

|

Description |

Radial Play Range |

APT Code |

|

Tight |

.0002-.0005” |

P25 |

|

Standard |

.0002-.0008” |

P28 |

|

Loose |

.0008-.0011” |

P811 |

ABEC Tolerances

Precision ball bearings are manufactured in accordance with industry standards and applicable features are in compliance with ABEC/ISO tolerances.

OUTER RING TOLERANCES

| Tolerance | |||||||||||||||||

| Outside Diameter(D) | OD +0.0000 | Width +0.0000 | Flange OD | Flange Width +0.0000 | |||||||||||||

| Over | INCL. | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) |

| 0 | 0.7087 | -.0003 | -.0003 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 | – | +.0050-.0020 | +.0000-.0010 | +.0000-.0010 | – | -.0020 | -.0020 | -.0020 |

| 0.7087 | 1.1811 | -.0004 | -.0003 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 | – | +.0050-.0020 | +.0000-.0010 | +.0000-.0010 | – | -.0020 | -.0020 | -.0020 |

| 1.1811 | 1.9685 | -.0005 | -.0003 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 | – | +.0050-.0020 | +.0000-.0010 | +.0000-.0010 | – | -.0020 | -.0020 | -.0020 |

| 1.9685 | 3.1496 | -.0005 | -.0004 | -.0002 | -.0002 | -.0050 | -.0050 | -.0015 | -.0010 | – | – | – | – | – | – | – | – |

Note: Dimensions listed are in inches

INNER RING TOLERANCES

| Tolerance | |||||||||

| Bore Diameter(d) | ID +0.0000 | Width +0.0000 | |||||||

| Over | INCL. | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) | ABEC 1(ISO P0) | ABEC 3(ISO P6) | ABEC 5(ISO P5) | ABEC 7(ISO P4) |

| 0 | 0.3937 | -.0003 | -.0002 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 |

| 0.3937 | 0.7087 | -.0003 | -.0002 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 |

| 0.7087 | 1.1811 | -.0004 | -.0002 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 |

| 1.1811 | 1.9685 | -.0005 | -.0003 | -.0002 | -.0002 | -.0050 | -.0050 | -.0010 | -.0010 |

Note: Dimensions listed are in inches

Note: Although ABEC/ISO tolerances ensure that bearings are manufactured within established guidelines, there are various other critical features that are not controlled by ABEC/ISO. These include features such as: raceway curvatures, pitch diameter, ball complement, ball grade level, friction, and retainer type.

Lubrication

Bearings are available with oil or grease lubrication. Grease is considered ‘lubed-for-life’ whereas oil is typically used in friction sensitive applications, when minimal lube is desired, or when there is a lubrication system like an oil bath. The main purposes of lubrication in bearings are:

- reduce friction and wear between the rolling elements and the rings thereby increasing bearing life

- act as a coolant and dissipate heat in the bearing as it is operating

- prevent corrosion

- help prevent foreign material from entering the internal components of the bearing

A list of commonly used oils and greases are shown in the chart below:

| Lube Type | apt Lube Code |

MANUFACTURER TRADE NAME |

BASE OIL | THICKENER | WORKING TEMP RANGE oF (oC) |

Viscosity (Oil Only) |

DROPING POINT oF (oC) |

NLGI | COLOR | CHARACTERISTICS |

| Oil | AF2 | Shell Oil Aeroshell 12 |

Diester | – | -65 to 250 °F (-54 to 121 °C) |

89 @ 130 °F | – | – | – | Light general purpose oil (MIL-PRF-6085) |

| Oil | 245 | Fuchs Lubricants Windsor Lube L-245X |

Diester | – | -65 to 250 °F (-54 to 121 °C) |

89 @ 130 °F | – | – | – | Light general purpose oil (MIL-PRF-6085) |

| Grease | MSRL | Kyodo Yushi Multemp SRL |

Diester | Lithium | -40 to 265 °F (-40 to 130 °C) |

– | 374 (190) | 3 (Channeling) |

Tan | Low noise and torque. |

| Grease | B325 | Exxon Mobil Beacon 325 |

Diester | Lithium Soap | -65 to 250 F (-54 to 120 C) |

– | 365 (180) | 2 (Non-Channeling) |

Light Tan | General purpose. |

| Grease | S220 | Exxon Mobil Mobilith SHC 220 |

Synthetic Hydocarbon | Lithium Complex | -40 to 302 F (-40 to 150 C) |

– | 509 (265) | 2 (Non-Channeling) |

Red | Multi-purpose. High load grease. |

| Grease | PREM | Exxon Mobil Polyrex EM |

Mineral | Polyurea | -20 to 350 F (-29 to 177 C) |

– | 500 (260) | 2 (Non-Channeling) |

Blue | Low noise. Electric motor grease. |

| Grease | 374C | NYE Lubricants Rheolube 374C |

Synthetic Hydrocarbon | Lithium Complex | -40 to 300 F (-40 to 150 C) |

– | 537 (280) | 4 (Channeling) |

Tan | Low Noise and Torque Low base oil separation |

| Grease | SRI2 | Chevron SRI-2 |

Petroleum | Polyurea | -20 to 350 F (-29 to 177 C) |

– | 470 (243) | 2 (Non-Channeling) |

Dark Green | General purpose. Water resistant. |

| Grease | MG28 | Exxon Mobil Mobil Grease 28 |

Synthetic Hydocarbon | Clay | -80 to 350 (-62 to 176) |

– | 450 (232) | 1 (Non-Channeling) |

Dark Red | Good low temperature torque. Wide temperature range |

| Grease | R500 | Nye Rheolube 500 | Petroleum Ester |

Sodium | -50 to 350 (-46 to 177) |

– | 395 (202) | 1 (Non-Channeling) |

Dark Blue | High speed/high temp. Good load carrying capacity |

| Grease | KPS2 | Kyodo Yushi PS #2 |

Petroleum Diester |

Lithium | -40 to 230 (-40 to 110) |

– | 374 (190) | 2 (Non-Channeling) |

White | Good low temperature torque. Low noise. |

| Grease | 240AC | Dupont Krytox 240 AC |

Fluorinated | Fluorote- | -30 to 550 (-35 to 288) |

– | NA | 2 (Non-Channeling) |

White | Stable at high temperature. |

| Grease | AG7 | Shell Areoshell 7 |

Diester | Microgel | -100 to 300 (-75 to 150) |

– | 500 (260) | 2 (Non-Channeling) |

Amber | Wide temperature range. Corrosion inhibiting. |

Basic Bearing Fatigue Life (Use the Bearing Life Calculator tool)

L10= (Cr/P)3 X 106 (Revolution)

L10h = 16667 / n · (Cr/P)3 (hours)

Where:

L10 = Basic rating life

Cr = Basic dynamic load rating (N)

n = R.P.M. (revolutions per minute)

L10h = Basic rating life in operating hours

P = Equivalent load (N)

The basic fatigue life of a rotating deep-groove ball bearing is given as:

General Fatigue Life Correction Factors

The L10 preload life of a bearing is normally adjusted as follows, according to real-world operating conditions:

|

Lna |

= |

a1a2 L10 |

where: |

Lna = adjusted bearing fatigue life |

a1 = Life correction factor for material and desired statistical reliability, the values for a1 being given below:

Values for Life Correction Factor a1

|

MATERIAL |

STATISTICAL RELIABLITY (%) |

|||||

|

90 |

95 |

96 |

97 |

98 |

99 |

|

|

Chrome: 52100 |

1.00 |

.62 |

.53 |

.44 |

.33 |

.21 |

|

Stainless: 440 |

.50 |

.31 |

.27 |

.22 |

.17 |

.11 |

a2 = Life correction factor for operating conditions. It has been empirically determined to have a value between 2.0 under ideal operating conditions and 0.2 where one or more of the following conditions may apply:

- The lubricant film thickness between the raceways and the rolling elements is low

- Bearing raceways are excessively misaligned Oscillatory motion

- Rotation speed of the bearing elements is very low

- Contamination or water is present in the bearing

Because there are many factors that determine the bearing life, the above figures should be used conservatively.

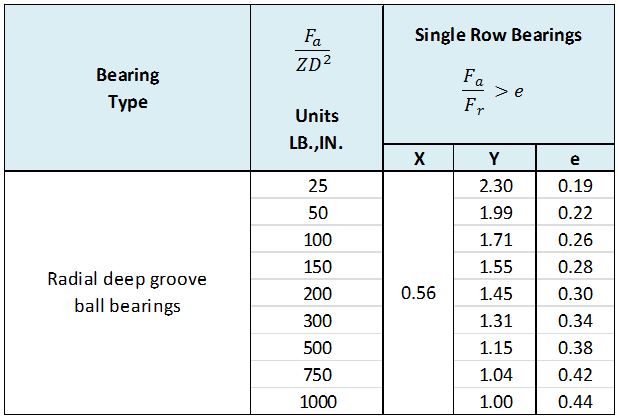

Equivalent Radial Load

In order to calculate an estimated life for a bearing you will need to use the Bearing Lifetime formula listed above. If your application involved purely a radial load applied to the bearing (no axial loading), then you can use the pure radial load to calculate the estimated bearing lifetime. In many situations, the application involves a combination of axial and radial loads. In these situations you may use the formulas and table below to combine the axial and radial loads into an Equivalent Radial Load that can be used in the bearing lifetime formula to calculate an estimated bearing life. (See Bearing Life Calculator.)

- Pr = Fr

- Pr = XFr +Yfa

When Fa/Fr < e, formula (a) is used. Otherwise formula (b) is used.

Nomenclature is as follows:

Pr = Equivalent Radial Load

V = rotation factor

X = radial factor

Y = thrust factor

Fr = radial load

Fa = thrust load

Z = number of balls

D = ball diameter in inches

Bearing Failure

Bearings can fail for many reasons. Based on our experience, ‘bearing failures’ will many times occur from inadequate lubrication, improper mounting, or improper bearing selection. Of course there are many more potential root causes of bearing failures, but in order to understand what is happening in your system, application-specific questions need to be answered and a bearing specialist should to be contacted. Please contact us so we partner with you and help determine an effective solution.

Mounting and Fitting

| Shaft Fits | ||||||||||

| Operating | Load | Speed | Shaft Diameter | Average Fit | Fit Range | Radial Load | Thrust Load | |||

| Conditions | Springs | |||||||||

| Rotating Shaft | Light | Low | B- 0.0002 | 0.0002L | 0 | P25 or P58 | P25 or P58 | |||

| B- 0.0004 | 0.0004L | |||||||||

| Light | High | B- 0.0001 | 0.0001L | 0.0001T | P25 or P58 | P25 or P58 | ||||

| Medium | Low to High | B- 0.0003 | 0.0003L | |||||||

| Heavy | High | B- 0.0000 | Line to Line | 0.0002T | P25 or P58 | P58 | ||||

| B- 0.0002 | 0.0002L | |||||||||

| Stationary Shaft | Normal | Low to High | B- 0.0002 | 0.0002L | 0 | See Rotating Housing | ||||

| B- 0.0004 | 0.0004L | |||||||||

| B = Nominal Bearing Bore | L = Loose Fit | T = Tight Fit | ||||||||

| Housing Fits | ||||||||||

| Operating | Load | Speed | Housing Diameter | Average Fit | Fit Range | Radial Load | Thrust Load | |||

| Conditions | Springs | |||||||||

| Rotating Housing | Light | Low to High | D- 0.0000 | Line to Line | 0.0002L | P25 or P58 | P58 | |||

| D- 0.0002 | 0.0002T | |||||||||

| Medium to Heavy | Low to high | D- 0.0001 | 0.0001T | 0.0001L | P25 or P58 | P58 | ||||

| D- 0.0003 | 0.0003T | |||||||||

| Stationary Housing | Light to Heavy | Low to High | D- 0.0000 | 0.0002L | 0 | See Rotating Shaft | ||||

| D- 0.0002 | 0.0004L | |||||||||

| D = Nominal Bearing OD | L = Loose Fit | T = Tight Fit | ||||||||

| Loads | Speeds | |||||||||

| Light Load | C/P < 25 | Low Speed | > 5000 RPM | |||||||

| Medium Load | C/P 15-25 | High Speed | > 1500 RPM | |||||||

| (Bearings w/OD <= 3/8″) | ||||||||||

| Heavy Load | C/P > 15 | High Speed | > 3000 RPM (Bearings w/OD > 3/8″) | |||||||

| C = Dynamic Road Rating | ||||||||||

| P = Radial Equivalent Load | ||||||||||

Preloading Bearings

Ball bearings are designed to be pre-loaded in some fashion to ensure that the rolling elements are rolling and that the bearings operate smoothly. There are three common methods to preload bearings:

- Dead weight preload using an adhesive

- Spring pre-load

- Solid clamp – using a mechanical fastener like a threaded shaft and nut to eliminate axial/radial play.